I jumped into my Jeep at lunch the other day and when I started it up, I heard that screeching sound that is a tell-tale sign that my serpentine belt on my 99 Jeep Cherokee was about to let go. I quickly shut the engine off and popped the hood which let some smoke start to creep around the edges of the hood. Serpentine belts are a pain because they wind through so many pulleys but that’s not too bad. I loosened up the belt tensioner pulley and pulled the belt off and began the inspection process to determine what when wrong. The belt was showing some signs of dry-rot since it had been on the engine for at least 7 years but it didn’t look like that was the root cause of the smoking belt.

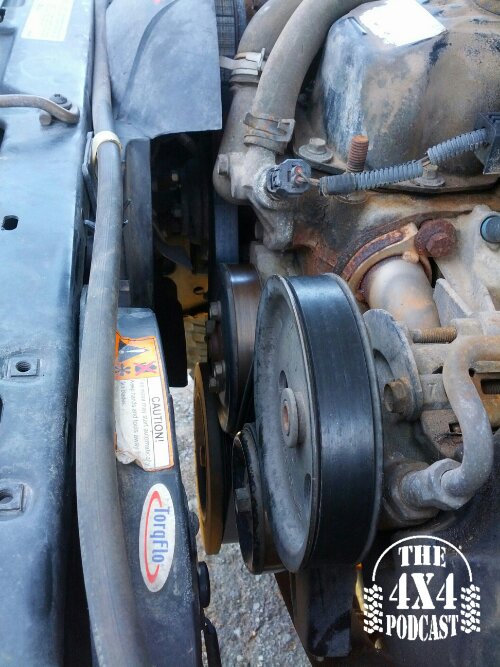

I started checking the pulleys to see if maybe a pulley bearing had seized which would cause a great load of friction which would lead to a belt failure. Sure enough, I discovered that the air conditioner compressor clutch had seized which roasted the bearings and caused my belt failure. I called around to the local parts places and picked up a new belt ($35) but I was having a hard time finding a new AC compressor clutch and bearing. I later discovered that I was going to have to get a whole new compressor with clutch and bearing already installed. Working on the AC system does require a EPA 608 certification so that you aren’t accidentally releasing the refrigerant which is hazardous to the ozone – I do not have the EPA certification. So I called around to some local shops for an estimate and let them know exactly what was needed to solve my issue. The lowest estimate I received was over $570 – OUCH!

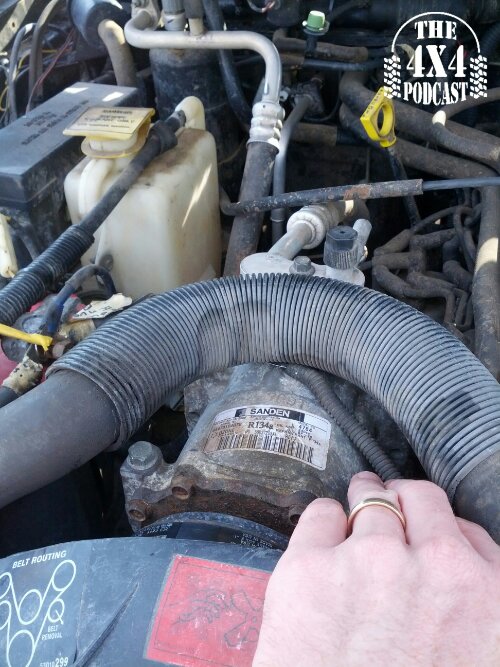

I already had my new $35 belt so I went back to my parts places, AutoZone, Advance Auto Parts and NAPA and they were all around $210 for a new AC compressor. Then my wife reminded me that someone from the church we attend co-owns a salvage yard. I called up Eiss Brothers Auto Parts in Watertown, NY and found a used compressor for $135 + core charge – WIN! The next problem to solve was how to evacuate the system so I don’t have to live with the mental burden of being personally responsible for killing all the polar bears, penguins destroying the rainforests by depleting the ozone with my R-134 AC refrigerant. Fortunately I have a few friends that have the certification and the recovery machine so problem solved!

Replacing the compressor is extremely simple and only took me 30 minutes from start to finish. The system had already been evacuated and the belt had been removed. All that was left was removing the four long bolts from the compressor that go into the bracket, disconnecting the refrigerant hoses and then disconnecting the electrical connection. I was a bit clumsy in holding the old compressor which let to me spilling some of the oil down the bumper so if you attempt this job, be sure to take care not to spill excess oil and make a mess – more on this and how Blue Ridge Overland Gear helped me keep things clean and tidy at the end of my story.

I dropped the new (used) compressor on to the bracket and installed it in reverse order as the removal. Now once I actually go back and have new refrigerant and oil added to the compressor, I will also be replacing the O-rings to ensure I can enjoy a nice long, leak-free AC system. For now though, I just needed to get the compressor with working clutch and pulley installed so that I can drive the Jeep and my wife and have her Suburban back. But for now, the compressor was installed and allowing me to route the 30 foot long (this might be an exaggeration) serpentine belt which will give me all the accessories back making the Jeep drive-able. You have to remember that the belt also drives the power steering and charging system – both necessary to drive a vehicle on 35” mud tires more than 2 miles.

Once everything was tightened down, belt installed and tension adjusted I was ready to fire up the engine for a quick test – it roared to life with only normal engine sounds so everything was good to go! Here’s how the cost has broken down so far:

· New Belt – $35 – AutoZone

· Used Compressor – $135 + core – Eiss Brothers http://eissbrothers.com/

· AC Refrigerant ~ $50 – AutoZone or Advance Auto Parts

· Edible bait to entice buddy to help with EPA 608 certification and easy my conscience – Priceless

The last step in this process is to return the old compressor to Eiss Brothers and get my core charge back which means I have to transport this oil covered unit back to their warehouse without making a mess in the Jeep. I already have Husky Floor Mats so my floors are pretty well protected but I didn’t want all that oil to run around and make a bigger mess – enter Blue Ridge Overland Gear oil bag http://www.blueridgeoverlandgear.com/The-overland-oil-bag-p/21fb.htm. I have had this bag sitting in the back of my XJ with some motor oil, liquid wrench, coolant and power steering fluid for quite some time because I know that if any of those containers were to leak or burst, the mess would be contained inside the vinyl coated polyester bag. This was a perfect solution for hauling my compressor back to the shop and have peace of mind that the double stitched seems and VCP material would keep the compressor oil contained should it roll over while driving. I love the peace of mind knowing that I can transport some extra vital fluids for my Jeep without the worry of them leaking all over the other gear that I carry with me everywhere. I highly recommend that you pick up one of these bags because you know you should be carrying spare fluids on the trail and you know that it’s just a ticking time bomb of a mess that should be well contained.

Blue Ridge Overland Gear has constructed a phenomenal product, as usual. Here are the technical specs for the oil bag:

– 550 Milspec Paracord

– ITW Nexus Ghillie TEX (QASM)

– 5’x6’ plastic tarp. No Eyelets

– TW Nexus Sliders

– 500D Cordura

– VCP Vinyl Coated Polyester — What bouncy houses are made from

– Velcro™

– Bar-tack Milspec webbing